BT 2000 Series : Compact Multi-Range Battery Test Equipment

Battery Cycler Intro:

To meet the various requirements adopted in advanced battery research,

we developed a multi-range battery test equipment BT 2000 that can automatically

switch the current range in accordance with user settings to maintain consistent accuracy.

Various current settings mechanisms are tailored to material researches to improve the efficiency and flexibility of testing process.

- Innovative mechanical design; the smallest in the industry. It contains 32 channels of 5V/30A models in a 23”, 25U rack.

- Module replacement design.

- Output and measurement accuracy is within ±0.02% F.S.

- 4 ranges of current precision, customizable based on customer requirements.

- A data recording frequency of 1ms.

- Unlimited phase of pulse charging/discharging; the minimum width is 10ms.

- Capable of discharging batteries to negative voltage.

| Model | BT 2000 Series |

| AC Power | Customized According To Client Needs |

Loading RangeCharge Discharge | 0~100V* 0~100V* (Option: Discharge to Negative Voltage) |

Constant VoltageMaximum Resolusion Accuracy | Depend on Spec* 16 bit ± 0.02% F.S. |

Constant CurrentMaximum Multiple Ranges Resolusion Accuracy | Depend on Spec* 2~4 (Option) 16 bit ± 0.02% F.S. |

Constant PowerMaximum Resolusion Accuracy | Depend on Spec 16 bit ± 0.04% F.S. |

| Data Recording Time | 100ms (Option:10ms, 1ms) |

Switch Time between Charge and Discharge | <5ms |

| Communication Interface | Ethernet |

| Ambient | 23⁰C ± 2⁰C; 20~90HR |

| Optional Features | Constant Resistance、Dynamic Waveform Simulation、Pulse Charge/Discharge、 DCIR Measurement、ACIR Measurement、Voltage Ramp、Current Ramp、 Parallel Connections among Channels、BMS & Gas Gauge Data Collection、Chamber Integration、Data Analyzer |

| Accessory | BMS & Gas Gauge Data Collector、Auxiliary Voltage、Auxiliary Temperature、 Chamber、Customized Fixture、Auto-Calibrator、Alarm Buzzer |

*Accept customized request

| Model Name | Voltage(V) | Current(A) | |||

| Range1 | Range2 | Range3 | Range4 | ||

| BT 2000 5V/1A | 5 | 1 | 0.1 | 0.01 | 0.001 |

| BT 2000 5V/5A | 5 | 5 | 0.5 | 0.05 | 0.005 |

| BT 2000 5V/10A | 5 | 10 | 1 | 0.1 | 0.01 |

| BT 2000 5V/20A | 5 | 20 | 2 | 0.2 | 0.02 |

| BT 2000 5V/30A | 5 | 30 | 3 | 0.3 | 0.03 |

| BT 2000 5V/60A | 5 | 60 | 6 | 0.6 | 0.06 |

| BT 2000 5V/100A | 5 | 100 | 10 | 1 | 0.1 |

| BT 2000 5V/180A | 5 | 180 | 18 | 1.8 | 0.18 |

| BT 2000 5V/200A | 5 | 200 | 20 | 2 | 0.2 |

| BT 2000 5V/250A | 5 | 250 | 25 | 2.5 | 0.25 |

| BT 2000 5V/300A | 5 | 300 | 30 | 3 | 0.3 |

| BT 2000 5V/350A | 5 | 350 | 35 | 3.5 | 0.35 |

| BT 2000 5V/400A | 5 | 400 | 40 | 4 | 0.4 |

| BT 2000 5V/450A | 5 | 450 | 45 | 4.5 | 0.45 |

| BT 2000 5V/500A | 5 | 500 | 50 | 5 | 0.5 |

| BT 2000 20V/40A | 20 | 40 | 20 | 10 | 5 |

| BT 2000 20V/60A | 20 | 60 | 30 | 15 | 5 |

| BT 2000 60V/60A | 60 | 60 | 30 | 15 | 5 |

| BT 2000 60V/100A | 60 | 100 | 50 | 20 | 10 |

| BT 2000 100V/300A | 100 | 300 | 150 | 50 | 10 |

Constant Resistance

Dynamic Waveform Simulation

The feature allows researchers to better understand battery performance in real-world driving condition. In order to achieve the goal, charge/ discharge rapid switch technology is developed, and the less than 5ms switch time makes simulating battery charge/ discharge pattern in real-road conditions become possible. Major international EV testing standards such as Federal Urban Driving Schedule (FUDS) and Dynamic Stress Test (DST) from U.S. Advanced Battery Consortium (USABC) are built-in for drive simulation feature. In addition, users are capable of importing the battery charge/ discharge patterns from a field test, or even defining their own testing patterns.

Pulse Charge/Discharge

DCIR Measurement

High-power battery module DC internal resistance

ACIR Measurement

High-power battery module AC internal resistance

Voltage/ Current Ramp

Parallel Connections among Channels

BMS & Gas Gauge Data Collection

During battery modules/ packs testing, the Gas Gauge/ BMS data is retrieved and recorded.

The data obtained can be used as the condition for program step change or providing protection.

1. Supports communication protocols such as SMBus, I2C, HDQ etc. for IT batteries and Modbus, CANBus etc. for power batteries.

2. Supports CAN .dbc file editing and import.

Chamber Integration

The synchronous control of chambers can be achieved during the testing processes.

Temperature and humidity levels can be adjusted to simulate different environments for measuring the battery’s performance.

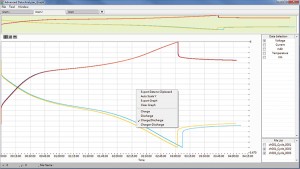

Data Analyzer

With Data Analyzer feature, a variety of test data presentations could be adjusted according to the needs of researchers, such as text and graphical reports, self-defined X and Y-axis parameters on graphs and graphs zoom-in / zoom-out. It also helps researchers to easily analyze the data from cycle test. Data from each cycle can be superimposed and drew on a single chart to produce a lifecycle test report. Evaluating test results and finding variation are easy! Moreover, test data can be exported in csv format and manipulated in the third-party software that researchers are familiar with, improving the data usability.

BMS/ Gas Gauge Data Collector

Records the static/ dynamic parameters of the BMS in energy/ power batteries. It supports SMBus, I2C, HDQ, Modbus, CANbus and other communication protocols that are commonly used in energy and power batteries, and it is scalable. With GDA 300, users are allowed to define customized parameters as step cutoff condition while running battery test. Additional parameters can also be defined by researchers to collect and analyze advanced data.

| Model | iBox - G | GDA-300 |

| CH/ per Unit | 8CH | 4CH |

| CH/ per System | 256CH | 128CH |

| Mechanism Design | Rack/ Portable | Rack/ Portable |

| Communication Protocols (Battery) | SMBus/ I2C / HDQ | SMBus/ I2C / HDQ |

| Communication Protocols (PC) | Ethernet/ Wifi | RS-485 |

| Communication Speed | 2Sec / 8CH* | 5Sec / 16CH |

| Number of parameters | 47 | 47 |

| Temperature Classification | 0~60°C | 0~60°C |

| SmartCHarge | Yes | Yes |

| SBS Write | Yes | Yes |

| Gauge Condition | Yes | Yes |

*iBox-G only

Auxiliary Voltage/ Auxiliary Temperature

Auxiliary voltage and auxiliary temperature are for collecting the voltage and temperature data of a single cell in the battery pack. Collected data can be used as step cutoff conditions while running the battery test, improving the flexibility of the production line and laboratory.

| Model | Auxiliary Voltage ES-100B |

| Channels | 24 |

| Measurement Range | ±64V,±32V,±8V |

| Measurement Resolution | 16 bit |

| Accuracy | 0.02% F.S. |

| Data Recording Time | 100ms (24CH) |

| Model | Auxiliary Temperature ET-100B |

| Channels | 24 |

| Measurement Range* | -50°C~125°C |

| Measurement Resolution | 0.1°C |

| Accuracy | ±1°C (-40°C~90°C) |

| Temperature Sensor | Thermistor |

| Supported Type | 103JT |

| Data Recording Time | 100ms (24CH) |

| Model | Auxiliary Temperature ET-100C | |||

| Channels | 16CH | 8CH | 8CH | 16CH |

| Scanning Speed | 4CH/s (16CH/4s) | 4CH/s (16CH/4s) | 4CH/s (16CH/4s) | 4CH/s (16CH/4s) |

| Accuracy | ±1°C | ±1°C | ±1°C | ±1°C |

| Resolution | 0.1°C | 0.1°C | 0.1°C | 0.1°C |

| Temperature Sensor | Thermocouple | RTD | Thermistor | Diode |

| Supported Type | Type J, K, E, N, R, S, T, B | PT-10, PT-50, PT-100, PT-200, PT-500, PT-1000, NI-120 | 44004 2.252kΩ, 44005 3kΩ, 44007 5kΩ,44006 10kΩ, 44008 30kΩ | 3904 |

| Measurement Range* | -265~800°C | -200~800°C | -40~150°C | -60~130°C |

*Depend on chosen thermal sensors

Universal/ Customized Fixture

According to customer requests, CTE provides a variety of universal fixtures and customized fixtures.The universal fixture is specially designed for cylindrical and prismatic batteries. It is suitable for a wide range of battery specifications, and can be adjusted by customers to work with the batteries to be tested. The non-base plate design allows the battery to be lifted, reducing the thermal impact on battery test. Moreover, the removable battery compartment also makes changing battery convenient and flexible. For customized fixtures, please contact Chen Tech Electric.

| Universal Fixture Application | Cylindrical and Prismatic Batteries |

| Suitable Battery Size (mm) | 18~100W*52D*55H |

| Number of Battery Holders | 4~24 |

| Loadable Current | Under 40A |

MaterialsOuter Frames Battery Box | Stainless Steel Bakelite |

Size (mm)Main Body Battery Box | 340W*423D*586H 319W*85D*239H |

Auto Calibrator ACP2 Series

ACP is especially designed to improve the efficiency and precision of calibration for CTE test equipment. It is applicable for CTE equipment with maximum voltage under 20V and maximum current lower than 100A. Its flexible and scalable design can be expanded to include up to 8 meters, thus ACP is capable of calibrating 8 testing channels simultaneously, which greatly reduces labor cost and time. Also, removable shunts and meters are built-in, making it easy to calibrate and maintain.

| Model | ACP2 L Series | ACP2 N Series | ACP2 M Series | ACP2 B Series |

| AC Power | AC110/220V | AC110/220V | AC110/220V | AC110/220V |

| Applicable Spec | 20V/1A and less | 20V/3A~20A and less | 20V/20A~50A and less | 20V/50A~100A and less |

| Applicable | MCF Lite Series MCL2 Mini Series BT 2000 Series MCP Plus Series | MCB Series MCL2 Series MCL2 Mini Series ABT 1000 Series GBT 1000 Series BT 2000 Series MCP Plus Series | MCB Series MCL2 Series ABT 1000 Series BT 2000 Series MCP Plus Series | MCB Series MCL2 Series ABT 1000 Series BT 2000 Series MCP Plus Series |

Alarm Buzzer

Chamber

We collaborate with several 3-rd party chamber manufacturers such as Espec, Terchy, Giant Force, and TATO, and integrate their products into our system. Thus, users are capable of controlling chamber directly with iBest software.

You may also like…