PBT 1000 Series : Eco Series - EV / Power Battery Pack Test Equipment

Intro:

PBT 1000 is specially designed for the testing of power battery pack. It rapidly simulates electric vehicle in actual on-road driving conditions and obtains the performance of battery operation to ensure its applicability. The discharge energy during the testing is effectively recycled to improve electrical efficiency and reduce the burden of air-conditioning in the testing environment.

- Supports high-power testing, and the equipment output can reach up to 1,000V/1,000A

- Discharged energy returned to the grid, with an efficiency up to 95%

- Current response time (10%→90%) and charge/discharge switching time is lower than 2ms

- Support the international EV testing standards such as FUDS and DST, and allow to import user-defined driving scenarios

| Model | PBT 1000 Series |

| Capacity | 20, 30, 40, 50, 75, 100, 160, 250, 320, 400, 500kW |

| AC Power | 380VAC*, 50/60 Hz, 3Φ |

| Power Factor | > 0.99 |

Voltage

| 100, 200, 400, 600, 800, 1000V* 16 bit ± 0.1% F.S. |

Current

| ±200, ±600, ±800, ±1000A* 16 bit ± 0.1% F.S. |

| Data Recording Time | 100ms |

| Switch Time between Charge and Discharge | 2ms |

| Drive Simulation | FUDS, DST, and Customized Patterns |

| Bidirectional Converter Efficiency | Up to 95% |

| Communication Interface | CANBus (USB to PC) |

| Optional Features | Advanced Data Analysis, SOH Evaluation |

| Accessory | Auxiliary Voltage, Auxiliary Temperature |

*Accept customized request

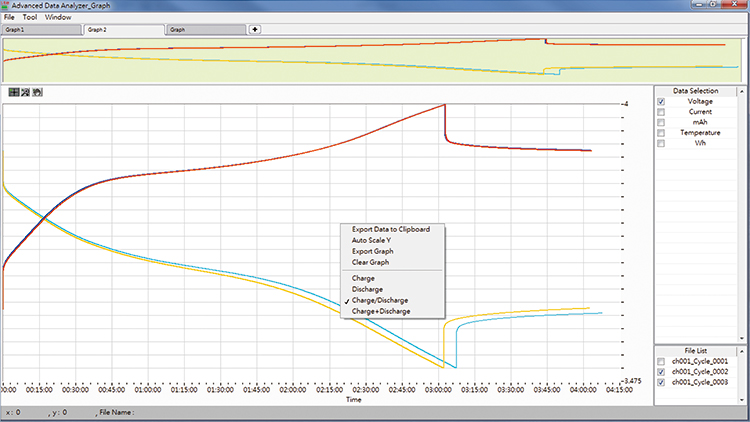

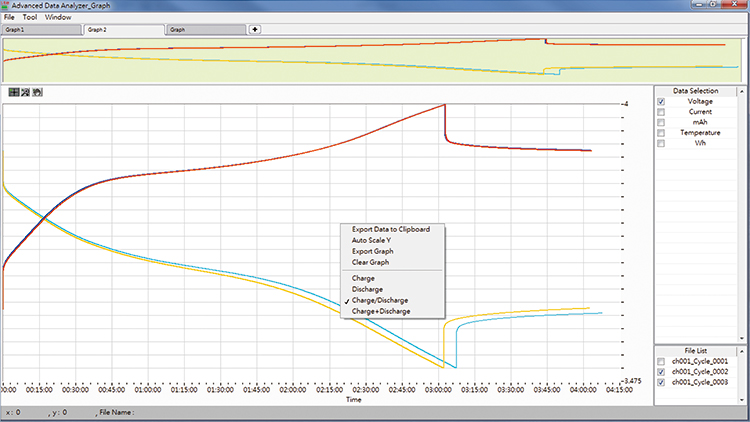

Advanced Data Analysis

With advanced data analysis feature, a variety of test data presentations could be adjusted according to the needs of researchers, such as text and graphical reports, self-defined X and Y-axis parameters on graphs and graphs zoom-in / zoom-out. It also helps researchers to easily analyze the data from cycle test. Data from each cycle can be superimposed and drew on a single chart to produce a lifecycle test report. Evaluating test results and finding variation are easy! Moreover, test data can be exported in csv format and manipulated in the third-party software that researchers are familiar with, improving the data usability.

SOH (State of Health) Evaluation

SOH evaluation feature helps researchers assess the SOH of used batteries in a more comprehensive way. Instead of solely capacity, 8 different parameters for battery cell/ 6 different parameters for battery pack are considered and measured while running SOH evaluation test, which provides a more precise result for researchers.

Auxiliary Voltage/ Auxiliary Temperature

Auxiliary voltage and auxiliary temperature are for collecting the voltage and temperature data of single cell in the battery pack. Every module contains 24 measurement points. The data recording time is 100ms and the accuracy is at 0.02% F.S. Collected data can be used as step cutoff conditions while running battery test, improving the flexibility of production line and laboratory.

| ES-100B Auxiliary Voltage | |

| Channels | 24 |

| Measurement Range | ±64V, ±32V, ±8V |

| Measurement Resolution | 16 bit |

| Measurement Accuracy | 0.02% F.S. |

| Data Recording Time | 100ms (24ch) |

| ET-100B Auxiliary Temperature | |

| Channels | 24 |

| Measurement Range | -50~150°C* |

| Measurement Resolution | 0.1 °C |

| Measurement Accuracy | ±1°C (-40~90°C) |

| Data Recording Time | 100ms (24ch) |

*Depend on chosen thermal sensors

- + Hightlight Features

-

Intro:

PBT 1000 is specially designed for the testing of power battery pack. It rapidly simulates electric vehicle in actual on-road driving conditions and obtains the performance of battery operation to ensure its applicability. The discharge energy during the testing is effectively recycled to improve electrical efficiency and reduce the burden of air-conditioning in the testing environment.

- Supports high-power testing, and the equipment output can reach up to 1,000V/1,000A

- Discharged energy returned to the grid, with an efficiency up to 95%

- Current response time (10%→90%) and charge/discharge switching time is lower than 2ms

- Support the international EV testing standards such as FUDS and DST, and allow to import user-defined driving scenarios

- + Specifications

-

Model PBT 1000 Series Capacity 20, 30, 40, 50, 75, 100, 160, 250, 320, 400, 500kW AC Power 380VAC*, 50/60 Hz, 3Φ Power Factor > 0.99 Voltage - Maximum

- Resolusion

- Accuracy

100, 200, 400, 600, 800, 1000V*

16 bit

± 0.1% F.S.Current - Maximum

- Resolusion

- Accuracy

±200, ±600, ±800, ±1000A*

16 bit

± 0.1% F.S.Data Recording Time 100ms Switch Time between Charge and Discharge 2ms Drive Simulation FUDS, DST, and Customized Patterns Bidirectional Converter Efficiency Up to 95% Communication Interface CANBus (USB to PC) Optional Features Advanced Data Analysis, SOH Evaluation Accessory Auxiliary Voltage, Auxiliary Temperature *Accept customized request

- + Optional Features

-

Advanced Data Analysis

With advanced data analysis feature, a variety of test data presentations could be adjusted according to the needs of researchers, such as text and graphical reports, self-defined X and Y-axis parameters on graphs and graphs zoom-in / zoom-out. It also helps researchers to easily analyze the data from cycle test. Data from each cycle can be superimposed and drew on a single chart to produce a lifecycle test report. Evaluating test results and finding variation are easy! Moreover, test data can be exported in csv format and manipulated in the third-party software that researchers are familiar with, improving the data usability.

SOH (State of Health) Evaluation

SOH evaluation feature helps researchers assess the SOH of used batteries in a more comprehensive way. Instead of solely capacity, 8 different parameters for battery cell/ 6 different parameters for battery pack are considered and measured while running SOH evaluation test, which provides a more precise result for researchers.

- + Accessories

-

Auxiliary Voltage/ Auxiliary Temperature

Auxiliary voltage and auxiliary temperature are for collecting the voltage and temperature data of single cell in the battery pack. Every module contains 24 measurement points. The data recording time is 100ms and the accuracy is at 0.02% F.S. Collected data can be used as step cutoff conditions while running battery test, improving the flexibility of production line and laboratory.

ES-100B Auxiliary Voltage Channels 24 Measurement Range ±64V, ±32V, ±8V Measurement Resolution 16 bit Measurement Accuracy 0.02% F.S. Data Recording Time 100ms (24ch) ET-100B Auxiliary Temperature Channels 24 Measurement Range -50~150°C* Measurement Resolution 0.1 °C Measurement Accuracy ±1°C (-40~90°C) Data Recording Time 100ms (24ch) *Depend on chosen thermal sensors

Application

Service

Download